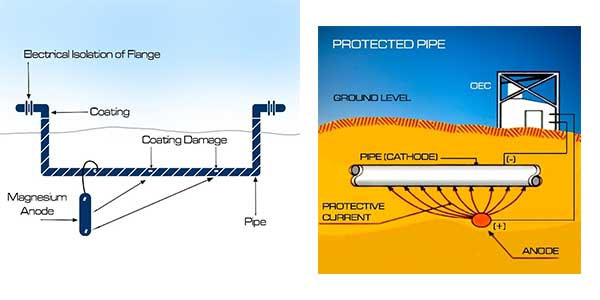

Corrosion is constantly attempting to degrade the performance of metal pipelines. The corrosion can be from dissimilar metals (galvanic corrosion), stray current corrosion from unintended sources of electricity, simple corrosion of similar metals (with varying anodic/cathodic sites), microbial induced corrosion and there are lesser-known types of corrosion.

Cathodic Protection Systems

To prevent simple corrosion and galvanic corrosion, owners of metal pipelines will often send an electrical field through the pipeline equalizing the electrical potential for all sites (this is commonly referred to as a cathodic protection system) that dramatically reduces the effects of corrosion. Owners will also coat the metal pipelines to reduce the cost of electricity needed to protect the pipeline.

The Role of Isolation within CP Systems

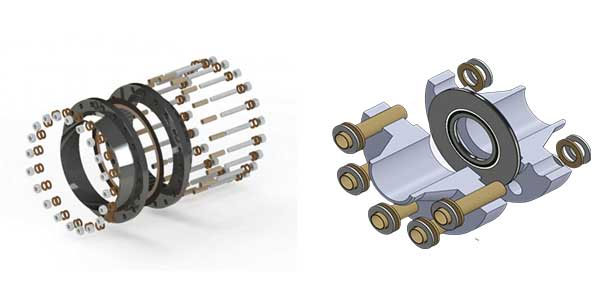

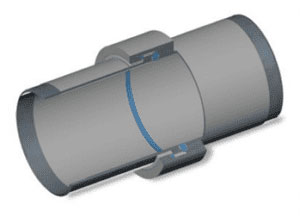

To further reduce the cost of electricity to protect the pipeline and to keep the electrical field to an effective level, isolation is often used in the form of flange isolation kits or monolithic isolation joints. Both products accomplish the same task, but flange isolation kits (FIKs) are predominately found in above ground installations while monolithic isolation joints (MIJs) are commonly found below ground. The terminology can change a bit regionally, but names like flange insulating kits, iso-kits, electrical isolation gaskets are often used to describe flange isolation kits and iso-joint, iso-block, monobloc, monoblock or insulating joint are all synonymous with monolithic isolation joints. Both FIKs and MIJs will stop the electrical flow through the pipeline and serve to keep the electricity in the areas that the pipeline owner wanted to protect. FIKs and MIJs break the metallic path in the pipeline and optimize the protection of the pipeline. Because they break the metallic path, they also stop stray current up to significant voltages. Breaking the metallic path as a function of an FIK or MIJ is very important because it will stop the electrochemical reaction between dissimilar metals. Pipelines will typically have valves, compressors, pumps, meters, pig launchers, etc. that are not made of the exact metallurgy as the pipeline itself. This difference in metallurgy brings with it differing potentials in the metals. With differing potentials and an electrolyte, the pipeline and the component are ripe to endure galvanic corrosion. By simply inserting a flange isolation kit (FIK), the metallic path between the component and the pipeline is eliminated and galvanic corrosion is then mitigated.

Microbial Induced Corrosion

When an FIK or MIJ is made to the pipe bore, this can dramatically reduce microbial induced corrosion (MIC) issues. Microbe colonies will build when there is an area to hold media such as a gap between flanges. If the FIK or MIJ is made to the pipe bore, the gap is eliminated and the potential for microbial colonies to grow is dramatically reduced.

There are adjacent benefits to using FIKs and MIJs in that by decreasing the amount of electricity needed to protect a pipeline, owners will likely see reduced issues with coating disbondment, and hydrogen induced corrosion. Both of which can be caused by higher levels of electrical flow through the pipeline.

Fire Safe Isolation Kits

There are many types of flange isolation kits and monolithic isolation joints on the market today. It is recommended that if the pipeline is carrying a flammable material that a fire safe flange isolation kit be used. If chemicals are added to the media to reduce microbial colonies from forming, to act as surfactants, to reduce iron sulfide build-up or for any other reason or if chemicals such as hydrogen sulfide are part of the media stream, it is important that the isolation kit is chemically compatible with the chemicals being used.

Role of Isolation Gasket on Emissions

Today, many companies are attempting to achieve greenhouse gas emission reduction goals. If the pipeline is part of that effort, it is recommended that glass reinforced epoxy (GRE) based isolation gaskets and phenolic isolation gaskets BE AVOIDED as these materials are permeable. It is also recommended that when an isolation product is used (either flange isolation kit or monolithic isolation joint), that a pipeline decoupler also be used to mitigate stray current or lightning effects that are beyond the capabilities of the isolation kit or joint.

A common flange isolation kit will consist of an isolating gasket, an isolating sleeve and isolating washers (preferably fully coated and encapsulated stainless steel washers).

Typical monolithic isolation joint:

The Academy of Joint Integrity are part of the Flexitallic Group of companies. For over 100 years Flexitallic has been at the forefront of the gasket and sealing industry, providing innovative sealing solutions across industry.

The Spiral Wound Gasket invented by Flexitallic, continues to underpin Leak Free Flanged Bolted Connections. Compression and Methane leakage performance tests are critical to ensure the competent bolting contractors achieve a right first time connection. Re work and re tightening can result in huge safety/ time and cost issues delaying projects and providing a backlog in maintenance.

A requirement of any gasket is the ability to recover under variable loads. The effects of pressure and temperature fluctuations, the temperature difference across the flange face, along with flange rotation, bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery, to maintain a seal under variable working conditions.

Please note attached document specifically advised as a key note to purchasing authorities who may find being frugal during the purchasing phase, may result in costly re work or loss of containment. Make sure you are confident in your purchasing decision as all Spiral Wound Gaskets are not manufactured the same.

Caprari constantly invests to ensure the safety of its products not only in terms of quality, but also as regards environmental sustainability and the protection of human health. This commitment is concretely demonstrated by our compliance with:

the REACH regulation“Registration, Evaluation, Authorisation and Restriction of CHemicals” which regulates the use and quantity of chemicals in products

the RoHS directive“Restriction of Hazardous Substances” which specifies quantities and concentrations of substances identified as hazardous in electrical and electronic equipment (EEE)

We thereby ensure the protection of consumers, workers and nature from the dangers of exposure to harmful chemicals, reducing the risk of environmental contamination and promoting long-term sustainability.

In particular, with regard to the Reach regulation, all Caprari products are registered and notified on the ECHA portal and can be consulted online.

Feel free to contact us for more information on how our water management solutions can meet your water supply demands.

As manufacturers, part of our job is to ensure that our equipment performs as designed, guaranteeing that customer needs are met.

FAT tests allow us to detect improvement opportunities, avoiding incidents in the final installation under working conditions. On the other hand, whenever we can, we deliver the equipment completely configured at the factory, facilitating commissioning and reducing possible risks related to an inappropriate configuration.

Viking Supply Ships AS needs new LARS systems for ROVs on board vessel Andreas Viking. Our new and improved L-LARS with our compact winch system is a perfect match for this upgrade.

Long story short, here are some highlights:

Special designed L-LARS

Very compact winch system

Evotec's efficient winch solution, EWDS

Our solutions are adaptable to new vessels and upgrades

«Viking Supply Ships wanted a high-end solution on limited space. We're a bunch of YES-people, and we could adapt our L-LARS winch solution with EWDS (Evotec Winch Drive Solution) to create the best handling system on board Andreas Viking." Sales Manager Offshore & Wind, Geir Henning Kalvatn says.

The Improvers at Evotec are ready to install the new and improved system this year. So far this year, we've been improving the offshore industry with contracts on eight new LARS systems in 2024 and 2025. And there's more in the pipeline.

CEO Jogeir Romestrand celebrates Evotec's enlarged position in the offshore market. «Our engineers and operators are improvers and create the best solution to solve your tasks efficiently and sustainably».